Udlala indima ebalulekile ekuthuthukiseni ukusebenza kwephampu uma ukhetha okulungileiphampu rotor isethi. Ngokukhetha ngokuhlakanipha, ungafinyelela kuze kufikeUkusebenza okuphezulu okungu-3.87%.futhi ujabulele izikhawu zokulungisa ezinde. Ucwaningo lwakamuva lubonisa ukuthi ama-rotor athuthukisiwe angakhuphula ngisho nokugeleza kwepompo ngo-25%, okugqugquzela inqubekelaphambili yangempela.

Okuthathwayo Okubalulekile

- Ukukhetha uhlobo olulungile lwephampu yerotha kanye nomklamo kukhulisa ukusebenza kahle, ukugeleza, nempilo yephampu kuzo zonke izinhlelo zokusebenza ezihlukene.

- Ukukhetha izinto ezifanele kanye nezingubo ezithuthukisiwe kuthuthukisa ukuqina kwe-rotor, kunciphisa ukugcinwa, futhi konga izindleko.

- Ukuhlola okuvamile nokukhetha i-smart rotor kusiza ukugwema ukuphuka, ukunciphisa ukusetshenziswa kwamandla, nokukhulisa ukusebenza kwepompo.

Indlela Ama-Pump Rotors Asebenza Ngayo Ezinhlotsheni Ezihlukene Zamaphampu

I-Centrifugal Pump Rotors

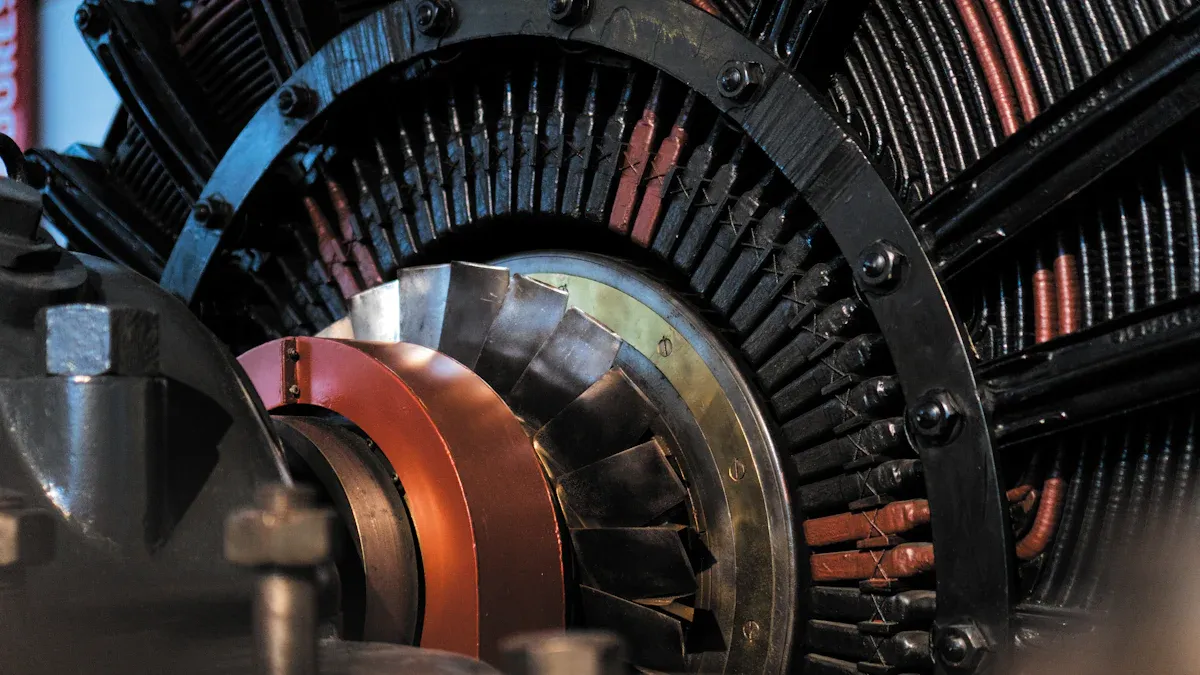

Ungavula amandla eqiniso okunyakaza koketshezi nge-centrifugalama-rotors epompo. Lawa ma-rotor, avame ukubizwa ngokuthi ama-impeller, ajikeleza ngokushesha ukuze enze amandla anamandla aphushela uketshezi ngaphandle ukusuka phakathi nendawo. Lesi senzo siguqula amandla emishini asuka kumotho abe amandla e-kinetic, amanzi anyakazayo noma olunye uketshezi ngepompo ukuya ohlelweni lwakho.

Uma ukhetha iphampu ye-centrifugal, ujoyina iningi lezimboni emhlabeni jikelele. Eqinisweni, amaphampu e-centrifugal abambe omkhulu65% ukwabelanawemakethe yephampu yezimboni ngo-2021. Uwabona yonke indawo—kusukela ezikhungweni zokuhlanza amanzi kuya ezimbonini zamakhemikhali—ngoba aphatha uketshezi oluningi kanye namazinga okugeleza.

Ithiphu:Ukukhetha idizayini ye-impeller efanele kungathuthukisa ukusebenza kahle nokuthembeka kwephampu yakho.

Ukusebenza kuyahlukahluka ngokusekelwe oketshezini kanye nejometri yephampu. Isibonelo, ucwaningo lubonisa ukuthi amanye amaphampu angama-centrifugal afinyelela aIkhanda eliphakeme ngo-3.3%.nezixazululo ezithile uma kuqhathaniswa namanzi. Kodwa-ke, ukunciphisa ijubane le-rotor kuholela ekwehleni okubonakalayo kokusebenza. Ukulingiswa kwezinombolo kuqinisekisa lokhu okutholakele, okubonisa ukuthi amaphampu e-axial-flow angafinyelela ukusebenza kahle kakhulu86.3%, kuyilapho eminye imiklamo ingase iwele ngaphansi kwama-80%. Lo mehluko ubalulekile uma ufuna ukwandisa okukhiphayo futhi unciphise ukusetshenziswa kwamandla.

Nakhu ukubuka okusheshayo kokucaciswa kwe-rotor yephampu ye-centrifugal:

| Ukucaciswa / Ipharamitha | Incazelo / Inani |

|---|---|

| I-Balance Tolerance Formula | U = 4W/N (U ku-oz-in, W = ethwele ijenali isisindo esimile, N = isivinini esikhulu sesevisi) |

| Ibanga le-ISO | Cishe i-0.7 (ISO 1940-1) |

| Imfuneko yokulinganisa ye-API 610 | Ukulinganisa okunamandla ku-ISO 1940-1 Ibanga lesi-2.5 noma okungcono |

| Ukubaluleka Kokulinganisa | Yehlisa ukudlidliza, ikhulisa ukuphila, futhi yehlisa isikhathi sokuphumula |

Ungabona ukuthi ukulinganisa okufanele kanye nokukhetha komklamo kukusiza ukuthi ufinyelele ukusebenza okushelelayo nempilo ende yesevisi. Uma utshala imali ku-rotor yepompo ye-centrifugal efanele, uzibekela impumelelo kunoma yiluphi uhlelo lokusebenza.

I-Positive Displacement Pump Rotors

Ungathembela kuma-rotor wepompo ahambayo uma udinga ukugeleza okuzinzile, okuthembekile—ngisho noketshezi oluwugqinsi noma olunamathelayo. Lawa ma-rotor abamba inani elinqunyiwe loketshezi futhi aluhambise epompo ngokuzungezisa ngakunye. Lo mklamo ukunika ukulawula okunembile kokugeleza, okwenza lawa maphampu afaneleke ezimbonini ezifana nokudla, ezemithi, nowoyela negesi.

Unemiklamo eminingi ye-rotor ongakhetha kuyo, ngayinye inamandla ahlukile:

| Uhlobo Lwephampu | Izimpawu ze-Rotor Design | I-Efficiency Insights Ngokusekelwe Kumklamo Nokufaneleka Kohlelo |

|---|---|---|

| I-Circumferential Piston | Amarobhothi awathinti noma axhunywe anezikhala; uphawu olwakhiwe phakathi kwama-stators nama-rotors | Ukusebenza kahle okuphezulu ku-viscosity ephansi; ibiza kakhulu |

| Lobe | Amarobhothi aseduze; ukucushwa kwe-lobe eminingi | Ilungele imikhiqizo ewugqinsi; ukusebenza kahle kakhulu ku-viscosity ephansi |

| I-Twin-Screw | Ama-spindle amabili asusa umkhiqizo nge-axially; ukushaya kwenhliziyo okuphansi | Ukuphatha okumnene, ukuguga okuphansi, izindleko eziphezulu |

Ukuhlolwa kwaselabhorethri kubonisa ukuthi amaphampu episton ayindilinga acwebezela ngoketshezi olune-viscosity ephansi, kuyilapho imiklamo ye-lobe ne-twin-screw ihamba phambili ngezinto eziwugqinsi. Ungabona lawa maphampu esebenza kuzo zonke izimboni, kusukela ekuhambiseni ushokoledi efektri kamaswidi kuya ekuphatheni uwoyela ongahluziwe endaweni yokuhluzwa.

Ucwaningo lwamaphampu episton ashayelwa umoya luveza ukuthi ukwengeza ama-accumulators we-pressure kunganciphisa ukukhuphuka komfutho kuze kufike ku-68%. Lokhu kusho ukusebenza okushelelayo nokuguga okuncane emishinini yakho. Uma ukhetha i-rotor efanele yokususa, uthola ukulawula, ukusebenza kahle, nokuthula kwengqondo.

I-Progressive Cavity Pump Rotors

Ungafinyelela imiphumela emangalisayo ngama-rotor wepompo ye-cavity eqhubekayo, ikakhulukazi uma ubhekene noketshezi oluyinselele noma udinga ukugeleza okuthambile, okungaguquki. Lawa ma-rotor anomumo we-helical oyingqayizivele ohambisa uketshezi ngochungechunge lwemigodi emincane evaliwe. Lo mklamo uphatha yonke into kusuka emanzini angcolile kuya kuma-slurries aminyene kalula.

Qaphela:Amaphampu we-cavity aqhubekayo ayisixazululo sakho sokusebenzisa lapho amanye amaphampu azabalaza.

Izinto ezintsha zakamuva zenze lawa ma-rotor ahlaba umxhwele nakakhulu. Isibonelo, idizayini ye-Vogelsang HiCone ikuvumela ukuthi ulungise indawo ye-rotor, ubuyisele ukucindezelwa kwangempela kanye nokwelula impilo yakho kokubili i-rotor ne-stator kuze kufike ku-izikhathi ezine. Ungenza lezi zinguquko ngokwenza noma ngokuzenzakalelayo, ugcine iphampu yakho isebenza njengento entsha futhi unciphisa isikhathi sokuphumula.

Nansi indlela ama-rotor wepompo athuthukile athuthukisa ngayo ukusebenza:

| Isici Sedatha Yezinombolo | Incazelo / Umphumela |

|---|---|

| I-Outlet Pressure | Imiklamo emisha iyafezwaingcindezi ephezulu yokuphumakunamamodeli ajwayelekile. |

| Isivinini sokuvuza kwe-Axial | Imiklamo ethuthukisiwe ibonisa ukuvuza okuncane, ithuthukisa ukusebenza kahle. |

| Inqubo Yokucindezela Kwangaphakathi | Ukucindezela okukhethekile kwandisa ukucindezela kokukhipha futhi kuthuthukisa ukunyakaza koketshezi. |

Uzuza ekusebenziseni amandla okuphansi, izikhawu zesevisi ezinde, kanye nezindleko zokulungisa ezincishisiwe. Ngokukhetha i-rotor yepompo ye-cavity eqhubekayo, unikeza isistimu yakho amandla okusingatha imisebenzi enzima ngokuzethemba nokusebenza kahle.

Isethi ye-Pump Rotor: Izinto, Idizayini, kanye Nokukhethwa

I-Common Rotor Materials

Ungakwazi ukuvula amazinga amasha okusebenza ngokukhetha izinto ezifanele zesethi yakho ye-pump rotor. Into ngayinye iletha amandla ahlukile, futhi ukukhetha kwakho kulolonga ukuqina kwephampu, ukusebenza kahle, kanye nezindleko. Ukuze uthole amanzi ahlanzekile, uvame ukubonaama-rotor enziwe ngensimbi eyinsimbi, i-aluminium, ithusi, insimbi engagqwali, noma i-polymer. Uma uphatha amanzi ane-turbid, ama-polymers angase angabi yisinqumo esingcono kakhulu. Uma uhambisa amanzi ngezinto eziqinile, i-aluminium ayifaneleki kangako. Ngamanzi ashisayo, insimbi, ithusi, nensimbi engenasici. Emanzini olwandle, ithusi noma insimbi engagqwali igqama, kuyilapho insimbi ewuketshezi iwa. Amaphampu ephuli kanye ne-whirlpool adinga izixhumi ze-polymer ukuze amelane nemiphumela enzima ye-chlorine.

Izinto ezithuthukisiwe ezifanaizinhlanganisela ezihlanganisiwezishintsha umdlalo. Manje usungakwazi ukuhlanganisa izinsimbi nama-polymers ukuze uqinise ukuqina futhi unciphise ukungqubuzana. Izinto ezivikelayo ezifana ne-tungsten carbide, ezisetshenziswa ngokufafaza okushisayo noma ukufakwa komhwamuko wamakhemikhali, kwenza i-rotor yakho yepompo iqine ngokumelene nokuhuzuka nokugqwala. Lezi zindlela ezintsha zikusiza ukuthi usebenzise amaphampu isikhathi eside, ngisho nasezimweni ezinzima.

Ithiphu:Inketho efanele yezinto ezibonakalayo inganweba impilo yephampu yakho futhi inciphise izindleko zokulungisa.

Ucwaningo lwezibalo luyabonisaI-E-glass fiber iyonga kakhulu futhi isetshenziswa kabanziku-rotor composite. Amafayibha ekhabhoni akunikeza amandla aphakeme nokuqina, ikakhulukazi lapho ukukhathala kuwukukhathazeka, kodwa abiza kakhulu futhi angase agle. Izintambo ze-Aramid zinikeza ukuqina okukhulu kanye nokumelana nomthelela, nakuba zibuthakathaka ekucindezelekeni. Inhlanganisela ye-Hybrid ikuvumela ukuthi ulinganise izindleko, amandla, nokuqina. Idatha yokukhathala igqamisa isidingo sekhwalithi ephezulu yokukhiqiza kanye nokuhlolwa kwesikhathi eside ukuze uqinisekise ukuthi isethi yakho ye-pump rotor ihlala ithembekile.

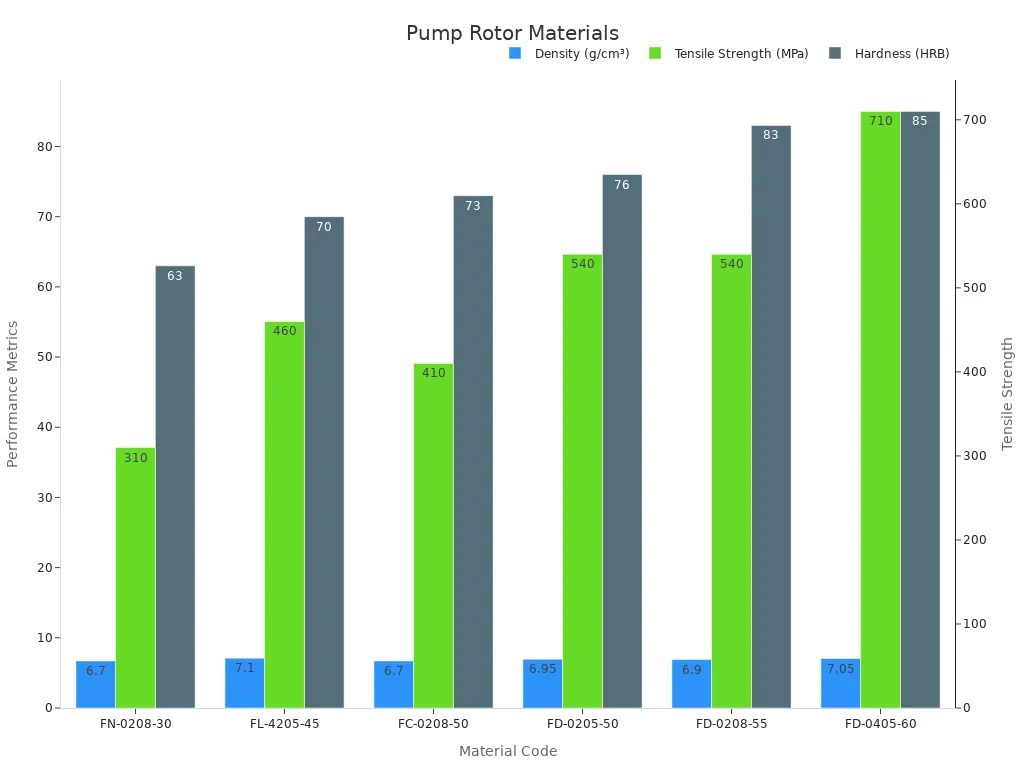

Ungabona umehluko kuukusebenza kwempahla kuthebula elingezansi:

| Ikhodi Yento | Ukuminyana (g/cm³) | Amandla Okuqina (MPa) | Ukuqina (HRB) |

|---|---|---|---|

| FN-0208-30 | 6.70 | 310 | 63 |

| FL-4205-45 | 7.10 | 460 | 70 |

| FC-0208-50 | 6.70 | 410 | 73 |

| FD-0205-50 | 6.95 | 540 | 76 |

| FD-0208-55 | 6.90 | 540 | 83 |

| FD-0405-60 | 7.05 | 710 | 85 |

Ungakwazi futhi ukuqhathanisa lezi zakhiwo ngokubuka:

Ukuhlolwa kokuqina kwakamuva kuma-graphite rotor kubonisa lokhoukukhetha kwezinto ezibonakalayo kuthinta ukuthi isethi ye-pump rotor yakho ihlala isikhathi esingakanani. Isibonelo, uhlobo olulodwa lwe-graphite rotor lulahlekelwe kuphela u-36.9% wezinto zalo ngemva kwemijikelezo engaphezu kuka-1,100 futhi lwaqhubeka lusebenza, kuyilapho ezinye zehluleka ngokushesha. Lokhu kufakazela ukuthi isinqumo sakho esibalulekile sithinta ngqo ukuthembeka kwephampu.

Izici ze-Rotor Design

Ungakwazi ukufeza ukusebenza kahle okuphawulekayo nokwethembeka ngokugxila ezicini zokuklama zesethi yakho ye-pump rotor. Ubunjiniyela besimanje bukulethela izindlela zokwelapha ezisezingeni eliphezulu ezifanai-thermal spray coating kanye ne-chemical vapor deposition. Lezi zindlela zinciphisa ukungqubuzana nokugqoka, okwenza ama-rotor akho ahlale isikhathi eside futhi asebenze ngokushelela.

Uzuza kuzinto zokugcoba ezenziwe ngokunemba ezinezithasiselo ezikhethekile. Lezi zigcina izingxenye ezihambayo zihlukanisiwe, ukungqubuzana okuphansi, futhi zandise impilo yesethi yakho yephampu yerotha. Amathuluzi wokubala afana ne-Finite Element Analysis (FEA) kanye ne-Computational Fluid Dynamics (CFD) akusiza ukuthi ulungiselele i-rotor geometry nezindlela zokugeleza. Lokhu kusho ukuthi amandla amancane amoshayo kanye noketshezi oluningi olunyakaziswa ngakho konke ukuzungezisa.

- Ukubekezelelana kokukhiqiza okuqinile kunciphisa ukugeleza nokuvuza, kukhulisa ukusebenza kahle.

- Amasistimu wokuqondanisa i-laser aqinisekisa ukuthi i-shaft yakho ijikeleza kahle, ivikela ingcindezi nokwehluleka kusenesikhathi.

- Imiklamo ye-rotor ne-chamber idala ukugeleza okubushelelezi, okuzinzile, okulungele uketshezi oluzwelayo noma oluwugqinsi.

- Izinzwa zesikhathi sangempela nokufunda komshini kubikezela izidingo zokunakekelwa, ukunciphisa isikhathi sokuphumula nokonga imali.

Qaphela:Ukusebenza kwengcindezi ephansi kumaphampu e-rotor kungakongela amandla afinyelela ku-30% futhi kwandise impilo yemishini ngo-20-25%.

Ijiyomethri yerotor emisha iphinde ilethe ukuthuthuka okulinganisekayo. Ngokwesibonelo,ukuthuthukisa i-blade pitch nokuqinaithuthukisa ukunemba kwe-flowmeter. Ukulungisa izilinganiso ze-hub-to-tip nama-engeli e-blade kunciphisa amaphutha futhi kugcina ukusebenza kuzinzile. Ukusebenzisa ama-algorithms ofuzo ukuze kucwengwe umumo wophephela kunqamule iphutha elingelona umugqa ngesigamu futhi kwehlise ubuncane bejubane lokugeleza elilinganisekayo. Le ntuthuko yedizayini ikusiza ukuthi uthole okuningi kusethi yakho ye-pump rotor.

Ukulingisa nokuhlolwa kwe-prototype kuqinisekisa lezi zinzuzo. Isibonelo, umklamo we-twin-rotor uzuze ai-coefficient yamandla ngaphezu kuka-0.44kanye nokusebenza okuthuthukisiwe kokuguqulwa kwamandla ngo-9% ngaphezu kwemiklamo evamile. Le miphumela ibonisa ukuthi ukukhetha kwedizayini ehlakaniphile kuholela ezinzuzweni zomhlaba wangempela.

Ukukhetha Isethi ye-Pump Rotor Engakwesokudla

Unamandla okuguqula ukusebenza kwesistimu yakho ngokukhetha isethi ye-pump rotor efanele. Qala ngokucabangela ukusebenza kahle nokusetshenziswa kwamandla. Amasethi asebenza kahle kakhulu anganciphisa izindleko zakho zokusebenza nomthelela wemvelo. Ngokwesibonelo, unomphela uzibuthe motor futha rotor amasethi ukufinyelelakuze kufike ku-94% ukusebenza kahle-10-12 wamaphesenti amaphuzu aphezulu kunamamotho ajwayelekile. Lokhu kungakongela kufikela ku-21% ekusebenziseni amandla futhi kunciphise ukukhishwa kwe-CO2 yonyaka ngamathani angaphezu kuka-32 kwezinye izinhlelo zokusebenza.

Uma ukhetha isethi ye-pump rotor, bheka lezi zindlela eziyinhloko:

- Ukusebenza kahle nokonga amandla

- Ukuguquguquka kokulawula ukugeleza kokushintsha izimfuno

- Ukuqina nokumelana nokugqoka impilo ende

- Umsindo ophansi wendawo yokusebenza ephephile, enethezeke kakhudlwana

- Umklamo ohlangene nokufakwa kalula

Kufanele futhisebenzisa iphampu yakho ngaphezu kuka-60% we-Best Efficiency Point (BEP)ukugwema ukudlidliza nokungazinzi. Gcina ukuchezuka kwe-rotor kuphansi ukuze uvikele ama-seal futhi uvimbele ukulimala. Ipompo enamandla nezakhiwo ze-baseplate zinciphisa ukungahambi kahle nokucindezeleka. Buka imithelela eguqukayo efana ne-resonance, ikakhulukazi ngamaphampu esivinini ahlukahlukene. Hlola njalo ukugqokwa, njengoba ukucaciswa okwenyuka kunganciphisa ukusebenza kahle. Imikhuba emihle yokufaka—izisekelo eziqinile, ukuqondanisa okufanele, namandla amapayipi amancane—isiza isethi yakho yephampu yerotha ukuthi isebenze kahle kakhulu.

Ugqozi:Zonke izinqumo ezihlakaniphile ozenzayo ekukhetheni nasekugcineni isethi ye-pump rotor yakho ikusondeza ekusebenzeni okuphezulu kanye nempumelelo ehlala njalo.

Izibonelo zezifundo zifakazela inani le-investimenti yakho. Ezimayini, ukushintshela kumasethi e-pump rotor asebenza kahle kakhulu konga amandla acishe abe ngu-42,000 kWh unyaka ngamunye futhi azikhokhele wona esikhathini esingaphansi kweminyaka emibili. Ezinhlelweni zikamasipala, lezi zithuthukisi zilingana nokongiwa kwamandla okushintsha amalambu e-incandescent angaphezu kuka-300 ngama-LED. Ungakwazi ukufeza imiphumela efanayo ngokugxila ku-rotor yepompo efanele esethelwe izidingo zakho.

Ushayela impumelelo yepompo ngokukhetha i-rotor efanele futhi uyigcine isesimweni esiphezulu.

- Ukuhlola okuvamile ngedatha ehlakaniphile kukusiza ukuthi ubone izinkinga kusenesikhathi futhi ugweme ukuphahlazeka okumba eqolo.

- Qaphelaukukhetha kwe-rotorkuthuthukisa ukusebenza kahle futhi konga imali ngokuhamba kwesikhathi.

- Izinzuzo ezincane ekusebenzeni kahlekungaholela ekongeni okukhulu kanye nesikhathi esincane sokuphumula.

FAQ

Kwenzekani uma uziba ukugcinwa kwe-rotor?

Usengozini yokuhluleka kwephampu kanye nokulungiswa okumba eqolo. Ukuhlola okuvamile kugcina isistimu yakho iqinile futhi ithembekile. Hlala umatasa futhi ubukele iphampu yakho ichuma.

Wazi kanjani ukuthi ungayishintsha nini i-rotor yepompo?

Ubona imisindo engavamile, ukugeleza okuphansi, noma ukuvuza. Themba imizwelo yakho engokwemvelo. Isenzo esisheshayo sikusiza ukuthi ugweme izinkinga ezinkulu futhi sigcine iphampu yakho isebenza kahle.

Ungakwazi yini ukuthuthukisa i-pump rotor yakho ukuze usebenze kangcono?

Nakanjani! Ungakhetha izinto ezithuthukisiwe noma imiklamo emisha. Ukuthuthukisa kuthuthukisa ukusebenza kahle futhi kwandise impilo yephampu yakho. Konke ukuthuthukiswa kukusondeza empumelelweni.

Isikhathi sokuthumela: Jul-09-2025