Umklamo kanye nomsebenzi wezimbobo zomshini kuyinkimbinkimbi, kuqukethe izingxenye eziningana eziyinhloko. Zenziwe ngobuso bezimbobo, ama-elastomer, izimbobo zesibili, kanye nehadiwe, ngayinye inezici nezinjongo ezihlukile.

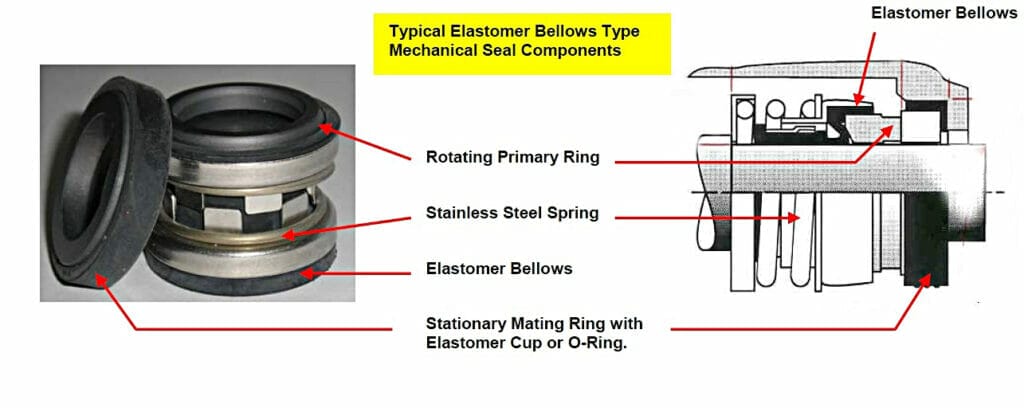

Izingxenye eziyinhloko zesivalo somshini zifaka:

- Ubuso obujikelezayo (Indandatho Eyinhloko):Lena yingxenye yesivalo somshini esijikeleza nomgodi. Ngokuvamile sinobuso obuqinile, obungagugi obenziwe ngezinto ezifana nekhabhoni, i-ceramic, noma i-tungsten carbide.

- Ubuso obungashintshi (Isihlalo noma Indandatho Yesibili):Ubuso obungaguquki buhlala buqinile futhi abujikelezi. Ngokuvamile benziwa ngezinto ezithambile ezihambisana nobuso obujikelezayo, okudala isikhombimsebenzisi sokuvala. Izinto ezivamile zifaka i-ceramic, i-silicon carbide, kanye nama-elastomer ahlukahlukene.

- Ama-Elastomer:Izingxenye ze-Elastomeric, njenge-O-rings kanye nama-gasket, zisetshenziselwa ukuhlinzeka ngokuvala okuguquguqukayo nokuphephile phakathi kwendlu engashintshi kanye nomgodi ojikelezayo.

- Izinto Zokuvala Zesibili:Lokhu kufaka phakathi ama-O-rings esibili, ama-V-rings, noma ezinye izinto zokuvala ezisiza ukuvimbela ukungcola kwangaphandle ukuthi kungangeni endaweni yokuvala.

- Izingxenye Zensimbi:Izingxenye zensimbi ezahlukahlukene, njengebhokisi lensimbi noma ibhendi yokushayela, zibamba uphawu lomshini ndawonye bese zilubopha emishinini.

Ubuso besivalo somshini

- Ubuso besivalo obujikelezayo: Indandatho eyinhloko, noma ubuso besivalo esijikelezayo, ihamba ndawonye nengxenye yomshini ojikelezayo, ngokuvamile umgodi. Le ndandatho ivame ukwenziwa ngezinto eziqinile neziqinile njenge-silicon carbide noma i-tungsten carbide. Ukwakheka kwendandatho eyinhloko kuqinisekisa ukuthi ingagcina amandla okusebenza kanye nokungqubuzana okubangelwa ukusebenza komshini ngaphandle kokuguqulwa noma ukuguguleka ngokweqile.

- Ubuso bophawu olumile: Ngokungafani nendandatho eyinhloko, indandatho yokubopha ihlala ingashintshi. Yenzelwe ukwakha umbhangqwana wokubopha nendandatho eyinhloko. Nakuba ingashintshi, yenzelwe ukuhambisana nokunyakaza kwendandatho eyinhloko ngenkathi igcina uphawu oluqinile. Indandatho yokubopha ivame ukwenziwa ngezinto ezifana ne-carbon, i-ceramic, noma i-silicon carbide.

Ama-Elastomer (ama-O-rings noma ama-bellows)

Lezi zinto, ngokuvamile ama-O-rings noma ama-bellows, zisebenza ekuhlinzekeni ukunwebeka okudingekayo ukuze kugcinwe uphawu phakathi kwe-mechanical seal assembly kanye ne-shaft noma i-housing yomshini. Zivumela ukungahambisani kahle kwe-shaft nokudlidliza ngaphandle kokubeka engcupheni ubuqotho be-seal. Ukukhethwa kwezinto ze-elastomer kuncike ezintweni ezahlukahlukene, kufaka phakathi izinga lokushisa, ingcindezi, kanye nohlobo loketshezi oluvalwayo.

Izimpawu Zesibili

Izivalo zesibili ziyizingxenye ezihlinzeka ngendawo yokuvala engaguquki ngaphakathi kwenhlangano yesivalo semishini. Zithuthukisa ukusebenza nokuthembeka kwesivalo, ikakhulukazi ezimweni eziguquguqukayo.

Ihadiwe

- I-Springs: Iziphethu zinikeza umthwalo odingekayo ebusweni besivalo, ziqinisekisa ukuthintana njalo phakathi kwazo ngisho nangaphansi kwezimo zokusebenza ezahlukahlukene. Lokhu kuxhumana njalo kuqinisekisa ukuthi isivalo sithembekile futhi sisebenza kahle kulo lonke ukusebenza komshini.

- Izigcini: Ama-retainer abamba izingxenye ezahlukene zesivalo ndawonye. Agcina ukuhambisana okufanele kanye nendawo yokuhlanganiswa kwesivalo, okuqinisekisa ukusebenza kahle kakhulu.

- Amapuleti e-glandAmapuleti ezindlala asetshenziselwa ukufaka uphawu emshinini. Asekela ukuhlanganiswa kophawu, alugcine luphephile endaweni yalo.

- Setha izikulufo: Izikulufo ezibekiwe ziyizingxenye ezincane, ezinezintambo ezisetshenziselwa ukubopha i-mechanical seal assembly ku-shaft. Ziqinisekisa ukuthi i-seal igcina indawo yayo ngesikhathi sokusebenza, ivimbela ukufuduka okungenzeka okungalimaza ukusebenza kwe-seal.

Ekuphetheni

Ingxenye ngayinye yesivalo somshini idlala indima ebalulekile ekuvaleni kahle kwemishini yezimboni. Ngokuqonda umsebenzi nokubaluleka kwalezi zingxenye, umuntu angaqonda ubunzima nokunemba okudingekayo ekuklameni nasekulondolozeni izivalo zomshini ezisebenza kahle.

Isikhathi sokuthunyelwe: Disemba 22-2023