Izisimbozo ze-cartridge ezisezingeni eliphezulu zithatha indawo yesimbozo se-shaft se-AES CURC,

Izimpawu ze-Cartridge mechanical, uphawu lwephampu yekhatriji, I-Pump Shaft Seal,

IZIMO ZOKUSEBENZA:

IZINGQONDO ZOKUSHISA: -20 ℃ kuya ku-+210 ℃

INCINDEZELO: ≦ 2.5MPa

Ijubane: ≦15M/S

IZINTO EZISETSHENZISWAYO:

IRINGI YESIKHATHI: IMOTO/ SIC/ TC

IRINGI EJWAYELEKILE: IMOTO/ SIC/ TC

ISIVALO SESIBILI: I-VITON/ EPDM/ AFLAS/ KALREZ

IZINGXENYE ZENTWASAHLOBO NEZENSIMBI: SS/ HC

IZICELO:

AMANZI AHLANZEKILE,

AMANZI OKUNGENA EZINTO EZINGENAYO,

I-Oyili kanye nolunye uketshezi oludlakadlaka olumaphakathi.

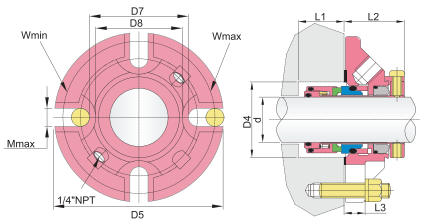

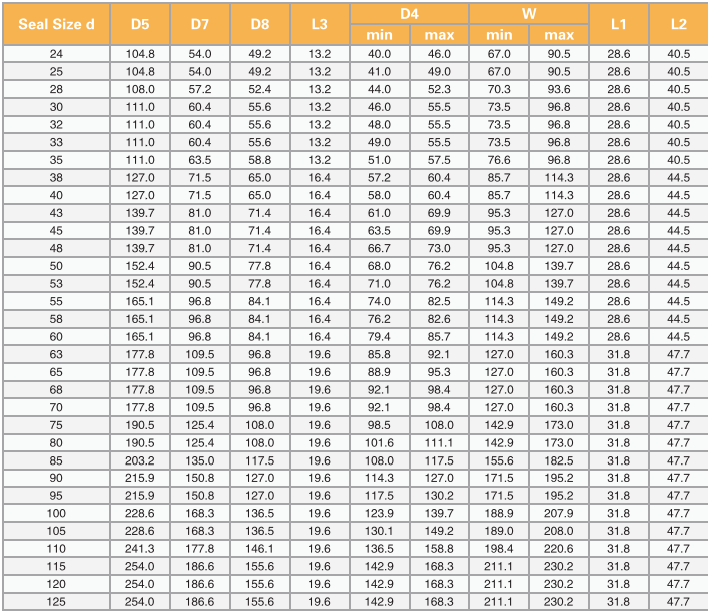

Ishidi ledatha le-WCURC lobukhulu(mm)

Izinzuzo ze-Cartridge Type Mechanical Seals

Izinzuzo ezinkulu zokukhetha izimbobo zekhatriji zesistimu yakho yokumboza iphampu zifaka:

- Ukufakwa okulula / okulula (Akukho uchwepheshe odingekayo)

- Ukuphepha okuphezulu kokusebenza ngenxa yesivalo esihlanganiswe ngaphambilini esinezilungiselelo ze-axial zokulungisa. Susa amaphutha okulinganisa.

- Kususe ithuba lokuphazamiseka kwe-axial kanye nezinkinga zokusebenza kwesivalo ezibangelwayo

- Ukuvimbela ukungena kokungcola noma ukulimaza ubuso besivalo

- Izindleko zokufaka ezincishisiwe ngesikhathi sokufakwa esincishisiwe = Izikhathi zokungasebenzi ezincishisiwe ngesikhathi sokulungiswa

- Kungenzeka ukunciphisa izinga lokuhlukaniswa kwephampu ukuze kufakwe uphawu esikhundleni salo

- Amayunithi ekhatriji alungiswa kalula

- Ukuvikelwa kwesikhwama somshafti/somshafti wamakhasimende

- Asikho isidingo semishayo eyenziwe ngokwezifiso ukuze isebenze uphawu olulinganiselayo ngenxa yesikhwama sangaphakathi seshafu sekhatriji yesivalo.